CITIC Heavy Industries (CITIC HIC) has been striving to technological innovation since 60 years ago. Our years of building up have led us to a respectable achievement in equipment performance, intelligent control, maintenance and spare parts supply services that have reached international advanced level within the mineral processing industry. Our crushers have been exported to a number of countries such as Sweden and Brazil, and widely used in coarse crushing operations of iron ores, copper ores, gold ores and molybdenum ores. Numerous projects that we have successfully executed are the evidence of our ability to provide safe, reliable, energy-saving and high-efficiency crushing equipment solutions.

testIndustry Leading Company of Mineral Crushers

- Developer of national standards for grinding mills

- Holder of more than 80 patents, including over 30 invention patents

- Winner of the First Batch of Single-item Champion Demonstration Enterprise in Manufacturing Grinding Mill, prescribed by National Ministry of Industry

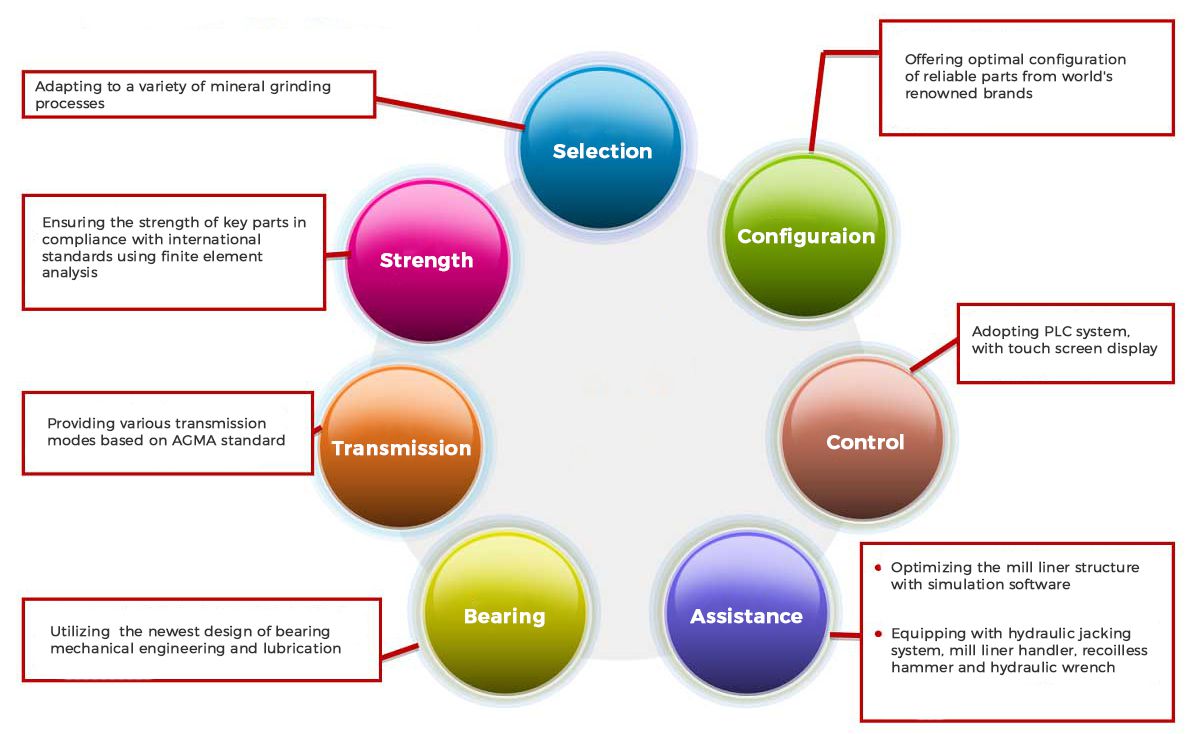

Key Features

- Developer of national standards for grinding mills

- Holder of more than 80 patents, including over 30 invention patents

- Winner of the First Batch of Single-item Champion Demonstration Enterprise in Manufacturing Grinding Mill, prescribed by National Ministry of Industry

Technical Specifications

Iterm One

Iterm two

Iterm There

Iterm Four

| Model | Mill diameter | Mill length | Mill effective volume | Max. ball loading capacity | Rotation speed | Motor power |

| mm | mm | m3 | t | r/min | kW | |

|

AG-40×□

|

4000 | 1400-3600 | 17-42 | 2-6 | 16.2 | 220-540 |

|

AG-45×□

|

4500 | 1600-4100 | 24-61 | 3-9 | 15.3 | 320-830 |

|

AG-50×□

|

5000 | 1800-4500 | 34-83 | 5-12 | 14.5 | 500-1200 |

|

AG-55×□

|

5500 | 1800-5000 | 42-112 | 6-16 | 13.8 | 630-1700 |

|

AG-61×□

|

6100 | 2400-5500 | 69-152 | 10-21 | 13.1 | 1050-2400 |

|

AG-67×□

|

6700 | 2600-6000 | 93-201 | 13-28 | 12.5 | 1500-3300 |

|

AG-73×□

|

7300 | 2800-6600 | 120-264 | 17-37 | 12 | 2000-4500 |

|

AG-80×□

|

8000 | 3200-7200 | 160-347 | 22-48 | 11.4 | 2800-6200 |

|

AG-86×□

|

8600 | 3400-7700 | 197-429 | 27-60 | 11 | 3500-7900 |

|

AG-92×□

|

9200 | 3700-8300 | 246-530 | 34-74 | 10.7 | 4500-10000 |

|

AG-98×□

|

9800 | 3900-8800 | 296-640 | 41-89 | 10.3 | 5600-12500 |

|

AG-104×□

|

10400 | 4200-9400 | 359-770 | 50-107 | 10 | 7000-15400 |

|

AG-110×□

|

11000 | 4400-9900 | 422-909 | 59-127 | 9.8 | 8400-19000 |

|

AG-116×□

|

11600 | 4600-10400 | 492-1064 | 69-148 | 9.5 | 10000-22000 |

|

AG-122×□

|

12200 | 4900-11000 | 580-1246 | 81-174 | 9.2 | 12000-27000 |

| Model | Mill diameter | Mill length | Mill effective volume | Max. ball loading capacity | Rotation speed | Motor power |

| mm | mm | m3 | t | r/min | kW | |

|

AG-40×□

|

4000 | 1400-3600 | 17-42 | 2-6 | 16.2 | 220-540 |

|

AG-45×□

|

4500 | 1600-4100 | 24-61 | 3-9 | 15.3 | 320-830 |

|

AG-50×□

|

5000 | 1800-4500 | 34-83 | 5-12 | 14.5 | 500-1200 |

|

AG-55×□

|

5500 | 1800-5000 | 42-112 | 6-16 | 13.8 | 630-1700 |

|

AG-61×□

|

6100 | 2400-5500 | 69-152 | 10-21 | 13.1 | 1050-2400 |

|

AG-67×□

|

6700 | 2600-6000 | 93-201 | 13-28 | 12.5 | 1500-3300 |

|

AG-73×□

|

7300 | 2800-6600 | 120-264 | 17-37 | 12 | 2000-4500 |

|

AG-80×□

|

8000 | 3200-7200 | 160-347 | 22-48 | 11.4 | 2800-6200 |

|

AG-86×□

|

8600 | 3400-7700 | 197-429 | 27-60 | 11 | 3500-7900 |

|

AG-92×□

|

9200 | 3700-8300 | 246-530 | 34-74 | 10.7 | 4500-10000 |

|

AG-98×□

|

9800 | 3900-8800 | 296-640 | 41-89 | 10.3 | 5600-12500 |

|

AG-104×□

|

10400 | 4200-9400 | 359-770 | 50-107 | 10 | 7000-15400 |

|

AG-110×□

|

11000 | 4400-9900 | 422-909 | 59-127 | 9.8 | 8400-19000 |

|

AG-116×□

|

11600 | 4600-10400 | 492-1064 | 69-148 | 9.5 | 10000-22000 |

|

AG-122×□

|

12200 | 4900-11000 | 580-1246 | 81-174 | 9.2 | 12000-27000 |

| Model | Mill diameter | Mill length | Mill effective volume | Max. ball loading capacity | Rotation speed | Motor power |

| mm | mm | m3 | t | r/min | kW | |

|

AG-40×□

|

4000 | 1400-3600 | 17-42 | 2-6 | 16.2 | 220-540 |

|

AG-45×□

|

4500 | 1600-4100 | 24-61 | 3-9 | 15.3 | 320-830 |

|

AG-50×□

|

5000 | 1800-4500 | 34-83 | 5-12 | 14.5 | 500-1200 |

|

AG-55×□

|

5500 | 1800-5000 | 42-112 | 6-16 | 13.8 | 630-1700 |

|

AG-61×□

|

6100 | 2400-5500 | 69-152 | 10-21 | 13.1 | 1050-2400 |

|

AG-67×□

|

6700 | 2600-6000 | 93-201 | 13-28 | 12.5 | 1500-3300 |

|

AG-73×□

|

7300 | 2800-6600 | 120-264 | 17-37 | 12 | 2000-4500 |

|

AG-80×□

|

8000 | 3200-7200 | 160-347 | 22-48 | 11.4 | 2800-6200 |

|

AG-86×□

|

8600 | 3400-7700 | 197-429 | 27-60 | 11 | 3500-7900 |

|

AG-92×□

|

9200 | 3700-8300 | 246-530 | 34-74 | 10.7 | 4500-10000 |

|

AG-98×□

|

9800 | 3900-8800 | 296-640 | 41-89 | 10.3 | 5600-12500 |

|

AG-104×□

|

10400 | 4200-9400 | 359-770 | 50-107 | 10 | 7000-15400 |

|

AG-110×□

|

11000 | 4400-9900 | 422-909 | 59-127 | 9.8 | 8400-19000 |

|

AG-116×□

|

11600 | 4600-10400 | 492-1064 | 69-148 | 9.5 | 10000-22000 |

|

AG-122×□

|

12200 | 4900-11000 | 580-1246 | 81-174 | 9.2 | 12000-27000 |

| Model | Mill diameter | Mill length | Mill effective volume | Max. ball loading capacity | Rotation speed | Motor power |

| mm | mm | m3 | t | r/min | kW | |

|

AG-40×□

|

4000 | 1400-3600 | 17-42 | 2-6 | 16.2 | 220-540 |

|

AG-45×□

|

4500 | 1600-4100 | 24-61 | 3-9 | 15.3 | 320-830 |

|

AG-50×□

|

5000 | 1800-4500 | 34-83 | 5-12 | 14.5 | 500-1200 |

|

AG-55×□

|

5500 | 1800-5000 | 42-112 | 6-16 | 13.8 | 630-1700 |

|

AG-61×□

|

6100 | 2400-5500 | 69-152 | 10-21 | 13.1 | 1050-2400 |

|

AG-67×□

|

6700 | 2600-6000 | 93-201 | 13-28 | 12.5 | 1500-3300 |

|

AG-73×□

|

7300 | 2800-6600 | 120-264 | 17-37 | 12 | 2000-4500 |

|

AG-80×□

|

8000 | 3200-7200 | 160-347 | 22-48 | 11.4 | 2800-6200 |

|

AG-86×□

|

8600 | 3400-7700 | 197-429 | 27-60 | 11 | 3500-7900 |

|

AG-92×□

|

9200 | 3700-8300 | 246-530 | 34-74 | 10.7 | 4500-10000 |

|

AG-98×□

|

9800 | 3900-8800 | 296-640 | 41-89 | 10.3 | 5600-12500 |

|

AG-104×□

|

10400 | 4200-9400 | 359-770 | 50-107 | 10 | 7000-15400 |

|

AG-110×□

|

11000 | 4400-9900 | 422-909 | 59-127 | 9.8 | 8400-19000 |

|

AG-116×□

|

11600 | 4600-10400 | 492-1064 | 69-148 | 9.5 | 10000-22000 |

|

AG-122×□

|

12200 | 4900-11000 | 580-1246 | 81-174 | 9.2 | 12000-27000 |

Case Study

We believe the projects that we have executed speak for themselves. CITIC HIC has engineered and provided 6 AG mills of Ø12.2m×11m (28000kW gearless drive) and 6 overflow discharge ball mills of Ø7.9×13.6m (2×9000kW gear drive) for Sino Iron Project in Australia. For Zijin Mining’s Duobaoshan Copper Mine project in Heilongjiang, we have manufactured and provided SAG mills of Ø11×6.4m (2×9000kW) and overflow discharge ball mills of Ø7.9×13.6m (2×9000kW) which have been well operating currently.

Brazilian Miner Vale SA

23 large-scale ball mills, Ø5.5×8.8m

Wengfu Phosphate Mine Project Phase II in Saudi Arabia (Ma'aden)

6 wet grinding rod mills, Ø4.6×6.7m

Vedanta Project in South Africa

1 SAG mill, Ø8.5×5.5m

Laos Phonesack Group's KSO Gold Mine Project (83,000t/d)

6 SAG mills, Ø8.8×4.8m

Mongolian Erdenet Mining Corporation's Copper Mine Project (20,000t/d)

SAG mill, Ø9.75×4.88m

Full-process Solution for Mineral Grinding

We believe the projects that we have executed speak for themselves. CITIC HIC has engineered and provided 6 AG mills of Ø12.2m×11m (28000kW gearless drive) and 6 overflow discharge ball mills of Ø7.9×13.6m (2×9000kW gear drive) for Sino Iron Project in Australia. For Zijin Mining’s Duobaoshan Copper Mine project in Heilongjiang, we have manufactured and provided SAG mills of Ø11×6.4m (2×9000kW) and overflow discharge ball mills of Ø7.9×13.6m (2×9000kW) which have been well operating currently.

Why Choose CITIC HIC's Grinding Mills

- High cost-effectiveness

CITIC HIC grinding mills are recognized as China’s Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of experience in developing and nurturing innovative technology. - High operating rate

The long life cycle of our products is based on the adoption of international standards, high-quality materials, state-of-the-art processing techniques. - Low-carbon & environmental-friendly processes

Intelligent control technology coupled with long-life wear-resistant materials results in low-carbon and eco-friendly operations. - High-efficiency service

Our service network is distributed all over the world, and our service team of seasoned professionals is reliable and willing to assist along the way. We are able to deliver quick response to customer needs and provide full life cycle support via online monitoring and diagnosing, product upgrading and continuous process improvement.